JG80L Railway Tamping Machine

8 Ton Hirail Crawler Excavator With Tamping Head

The hydraulic turnout tamping machine is suitable for tamping operations of complex and difficult turnout sections in line maintenance.

Features

1. Turnout switch parts, turnout connecting parts, turnouts and rail protection parts can be tamped. The machine is easy to operate, light in weight, high in operation efficiency and low in failure rate, and can meet the needs of railway ballast tamping operations.

2. The hydraulic tamping machine is mainly designed to meet the needs of passenger high-speed, heavy freight, and high-density heavy-duty rail structures.

3. The application of this machine to the line tamping operation can completely replace the traditional line maintenance tools, overcoming the shortcomings of the traditional line maintenance tools, such as high labor intensity, low operating efficiency, and poor tamping quality.

4. This hydraulic tamping machine has many advantages such as light weight, flexible operation, low failure rate, good tamping quality, and convenient access to the road.

Main Parameters

Length*width*height | 6100*2200*2650mm |

| Rated Power | 62.5KW |

Machine weight | 8100KG |

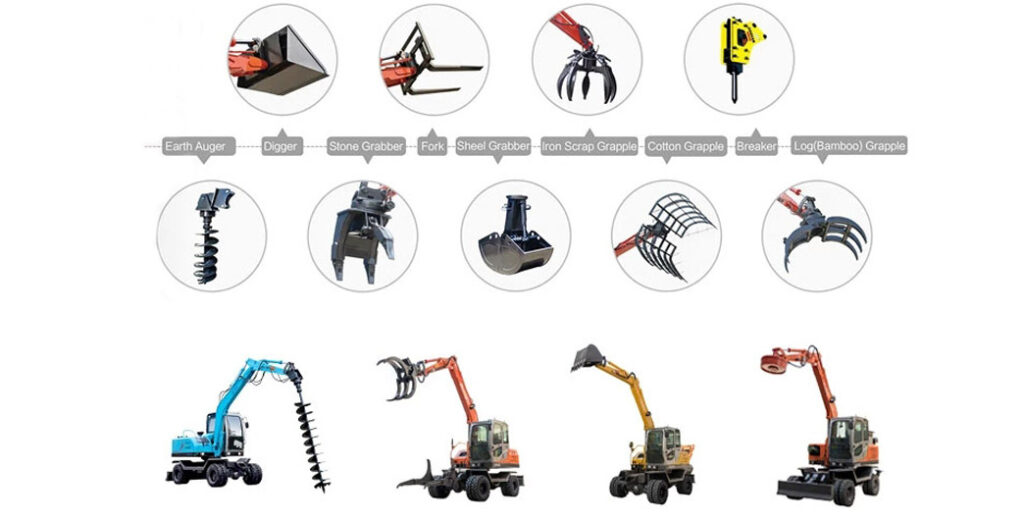

Options Attachments

We provide more optional parts to complete more kinds of work. We provide a variety of work tools such as grabs, forks, pulverizers, etc. to meet your various application needs. In addition, a variety of fixtures are provided to optimize the performance of the machine. The auxiliary hydraulic lines are arranged on the base of the boom, making the auxiliary hydraulic circuit easier to install, thereby reducing the time, parts and costs required for installing work tools.

Why Choose Us

1.Strict quality management produce effective and stable products to meet customers’ needs.

2. Strict detecting system and advanced inspection equipment.

3.Professional sales team, quality inspection & report, maritime logistics guidance.

4.We grants our clients a twelve-month-period or 2000-hours warranty for any machine purchased from us.

5.We offer perfect facilities and comfortable environment and can provide training services to different users.

Company

We are a leading manufacturer and exporter of wheel excavators, crawler excavators, sugarcane harvesters, sugarcane grab loaders, multi-function excavators. We have nearly 20 years of professional experience, and our products have been exported to many countries.

Workshop Display

Our company abides by the business philosophy of “quality first, customer first” to ensure product quality. We have rigorous production procedures, and each production process is carried out under strict quality inspection.Only after passing the inspection can they move on to the next procedure. At the same time, we insist on creating a neat, clean and safe working environment.

Process

Exhibition Show

Certificates